Mechanical Engineering / Process Engineering

· Optimisation through simulation ·

Most sub-areas of mechanical engineering, such as materials science, fluid mechanics, technical thermodynamics, technical mechanics can be taken into account without any problems when applying the numerical methods. ASD GmbH has extensive experience in the simulation of stresses on complete machines and their components. Above all, with regard to factors such as resource efficiency, durability, lightweight construction and recyclability, numerical simulation can help to uncover sustainable alternatives.

Process engineering deals with the technical and economic implementation of all processes in which a material conversion takes place. This includes the development and realisation of the corresponding plant construction as well as the calculation and optimisation of the mechanical, chemical, thermal and biological processes involved. For a necessary increase in efficiency in the design and development of process plants and subsystems, a wide range of simulations are available as indispensable analysis tools.

Automotive engineering

The ever-increasing demands in the areas of e-mobility, interior climate control, safety for passengers and passers-by, rigidity, vibration behaviour and acoustics lead to a high demand for research and development activities. In addition to the methods of numerical flow simulation

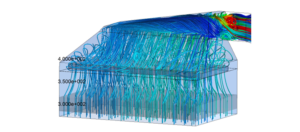

Reactors

The influence of design parameters and boundary conditions on the three-dimensional processes taking place in the reactor can be examined in detail by means of computer simulations.

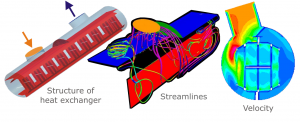

Heat exchanger

In order to optimize the efficiency of a heat exchanger, i.e. to heat up the material flow to be heated as much as possible and to cool down the other material flow as much as possible, the analysis of the