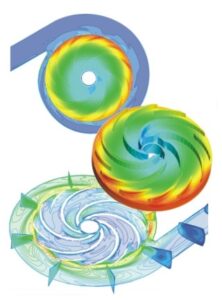

Numerical flow models can be used to analyze the complex processes involved in vaporization in an emergency anesthesia machine, taking into account the transfer of heat of vaporization and heat conduction in the walls. The pressure rise in the closed system due to the vapor volume is simulated, as well as the change in fluid properties with varying pressure and temperature conditions. The occurring condensation processes of the vapor on the cold wall are also captured in the system pressure.

Our simulation models reproduce the complex processes of subcooled boiling and provide, for example, detailed temperature distributions on the walls and in the liquid. They provide reliable decision support for design selection and optimization. The simulation results are validated with the help of experiments.