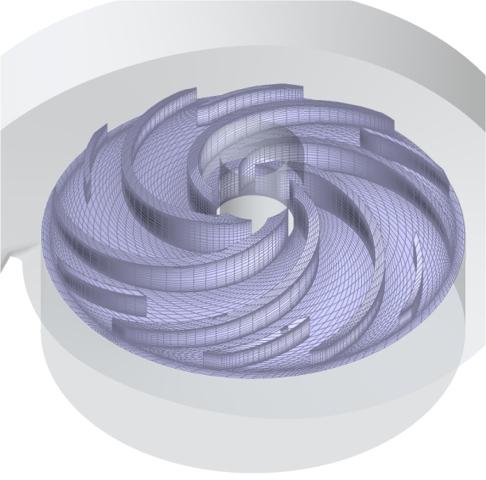

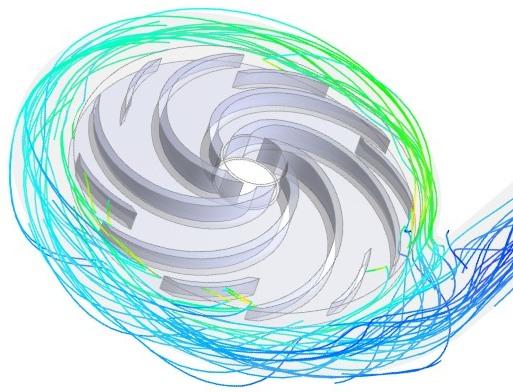

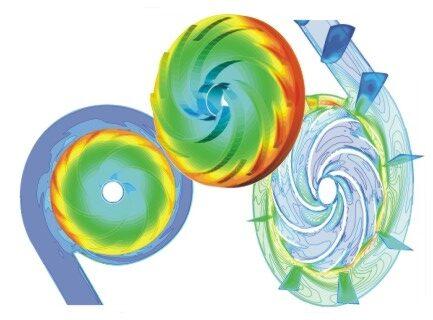

The flow characteristics and hydraulic properties of a blood pump as well as the damage parameters of blood (e.g. haemolysis index) can be realistically reproduced with the aid of 3D flow simulations using modern blood damage models.

The result of the simulations enables a three-dimensional finely resolved analysis of the speed, pressure and stress distribution in the entire pump. In addition to determining haemolysis rates and possible thrombus formation, the risk of thermal blood damage, e.g. due to bearing friction, is also predicted.

In the early 1990s, the Managing Director of ASD GmbH, Dr Catrin Bludszuweit-Philipp, developed one of the first numerical methods to enable a 3D analysis of blood pumps with regard to their haemolysis risk. Publications

ASD’s haemolysis models have been successfully validated in the FDA‘s Critical Path Initiative. [more]

ASD GmbH performs effective pump simulations and successful design optimisations for a wide variety of blood pumps, such as centrifugal blood pumps and axial pumps as cardiac support systems, as well as roller pumps and other displacement pumps.

ASD GmbH also uses simulation-based analysis to optimise the combination of a blood pump with an oxygenator and cannulas in an ECMO system in terms of functionality and haemocompatibility in order to minimise the patient load.