With a length of 8-14 mm and a diameter of 3-5 mm, dental implants must withstand masticatory forces of up to 500 N for decades.

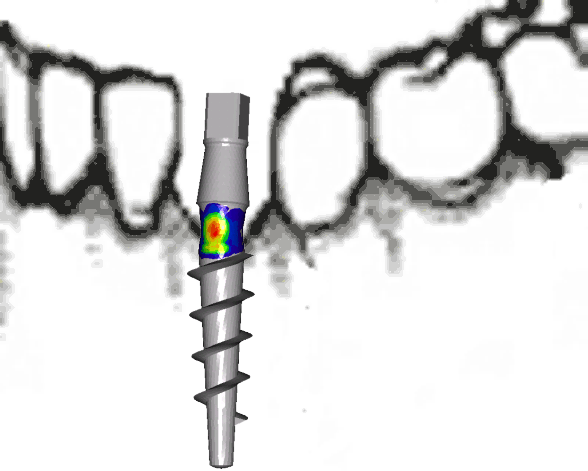

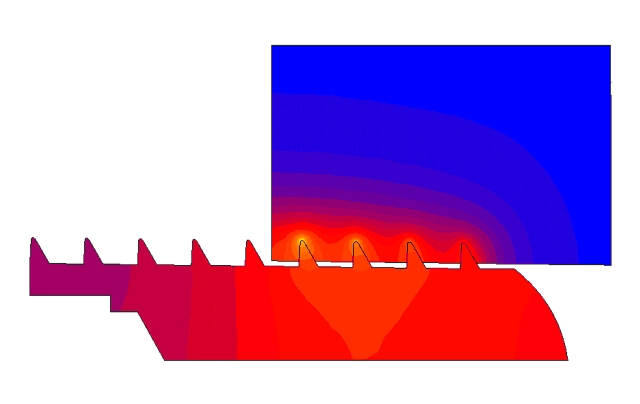

Our advanced simulation tools can be used to perform analyses of static strength, life time of implants, and bone interaction studies. For example, during screw insertion and consequently the assessment of thermal bone damage caused by this friction-induced heat input.

By taking into account DIN standards for the classical test setup of such implants (e.g. DIN EN ISO 14801), preload forces on multi-part implants as well as properties of the surrounding bone structure, the number of time-consuming tests in the approval process can be minimized.

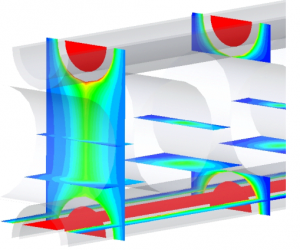

Stress distribution and deformation on implant and bone are available, which serve as a basis for estimating the static strength and service life of the implant or the bone damage potential and thus provide starting points for optimisation.

Calculated residual stresses on a bicortical screw after implantation and bending

Thermal behavior when screwing in an implant thread