Chemical and biological simulations

Especially in the fields of medical technology, biotechnology and process engineering, the interaction of biological or chemical processes with the dominant physical processes is of

The following posts include the selected tag:

Especially in the fields of medical technology, biotechnology and process engineering, the interaction of biological or chemical processes with the dominant physical processes is of

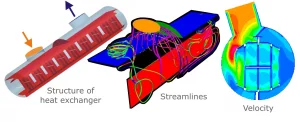

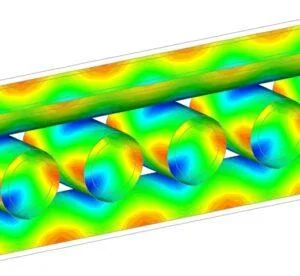

In order to optimize the efficiency of a heat exchanger, i.e. to heat up the material flow to be heated as much as possible and

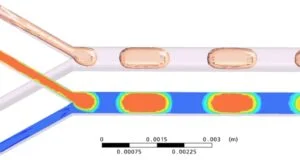

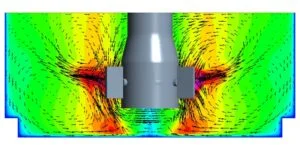

Microreactors are reactors with extremely small structures (internal dimensions < 1 mm). They perform tasks such as mixing, dispersing, gassing, chemical precipitation, heat transfer and

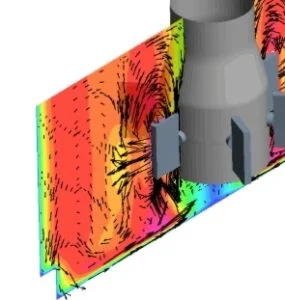

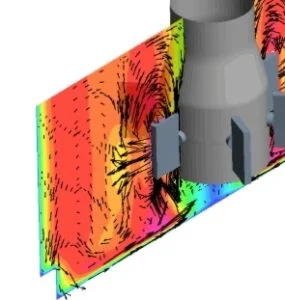

The filter effectiveness, taking into account the underlying physical fluid mechanical and thermal processes, can be effectively analysed and optimised using modern methods of numerical

Both the flow through a wide variety of bioreactor systems and their supply with nutrient medium as well as the temperature control or the choice

The influence of design parameters and boundary conditions on the three-dimensional processes taking place in the reactor can be examined in detail by means of computer simulations.

The ever-increasing demands in the areas of e-mobility, interior climate control, safety for passengers and passers-by, rigidity, vibration behaviour and acoustics lead to a high

Fluid Structure Interaction (FSI) combines the description of a flow with the interaction of a solid. The methods CFD and FEA are applied simultaneously to

Numerical flow simulations (Computational Fluid Dynamics Simulations – CFD Simulations) enable three-dimensional insights into complex flow processes, which could not be realised experimentally or only